EXEMPLE DE CONSTRUCTII REALIZATE DIN MATERIALE COMPOZITE SANDWICH FABRICATE PRIN PROCEDEE CLASICE

Preocupari privind utilizarea materialelor compozite si a panourilor sandwich compozit (asemanatoare cu cele brevetate) in constructii mai exista in lume (Anglia, India, China, Japonia, S.U.A., Emirate Arabe etc.). Acestea privesc in special utilizarea acestor materiale pentru realizarea unor constructii mari si cu grad ridicat de rezistenta la seisme.

In Anglia s-au realizat multe constructii din matweriale compozite si panouri sandvich astfel:

– Firma Scott Bader Ltd. a realizat dupa un proiect al firmei COPA o scoala in Davwentry;

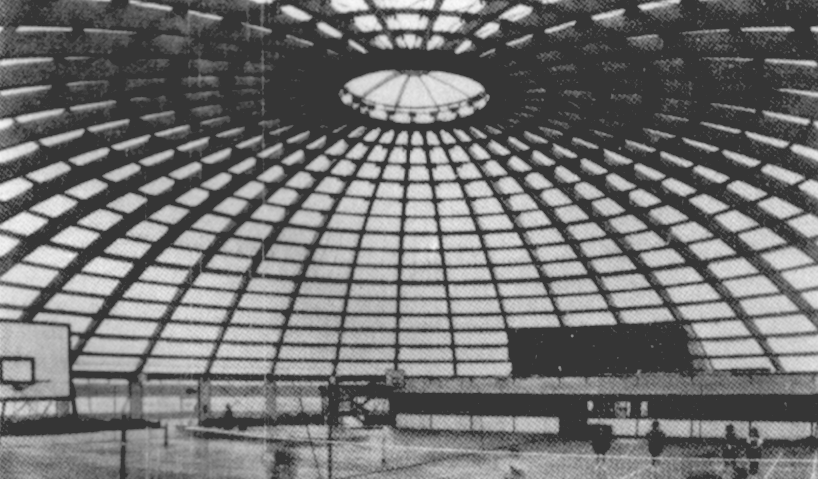

– Firmele Scott Bader Ltd. si Hooker Chemical au realizat din panouri sandwich compozit cupola de la Sports Center din Newcastle;

– Firma Maunsell Structural Plastics Maunsell House a realizat un podul Bromley South Bridge cu o lungime de 210 m si latime de 42 m;

– Firma Maunsell Structural Plastics Maunsell House a realizat o autostrada de 15 Km care trece peste estuarul raului Avon si care leaga autostrazile M4 (la Awkley) si M5 (la Lawrence) de terminalul de imbarcare din dana de la Pilning.

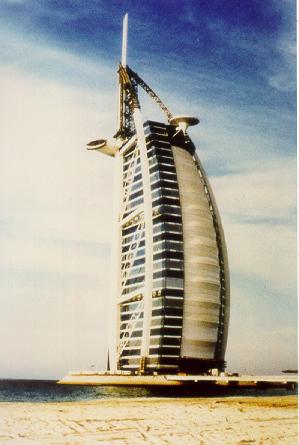

In Emiratele Arabe (Dubai) s-a construit hotelul Arabian Tower Hotel folosind panouri sandwich compozit.

In SUA s-au realizat numeroase costructii din panouri sandwich conpozit cum ar fi:

– Constructie industriala din Sticla/Poliester – Proiect si executie Stanlei Oswitch-Whessoe;

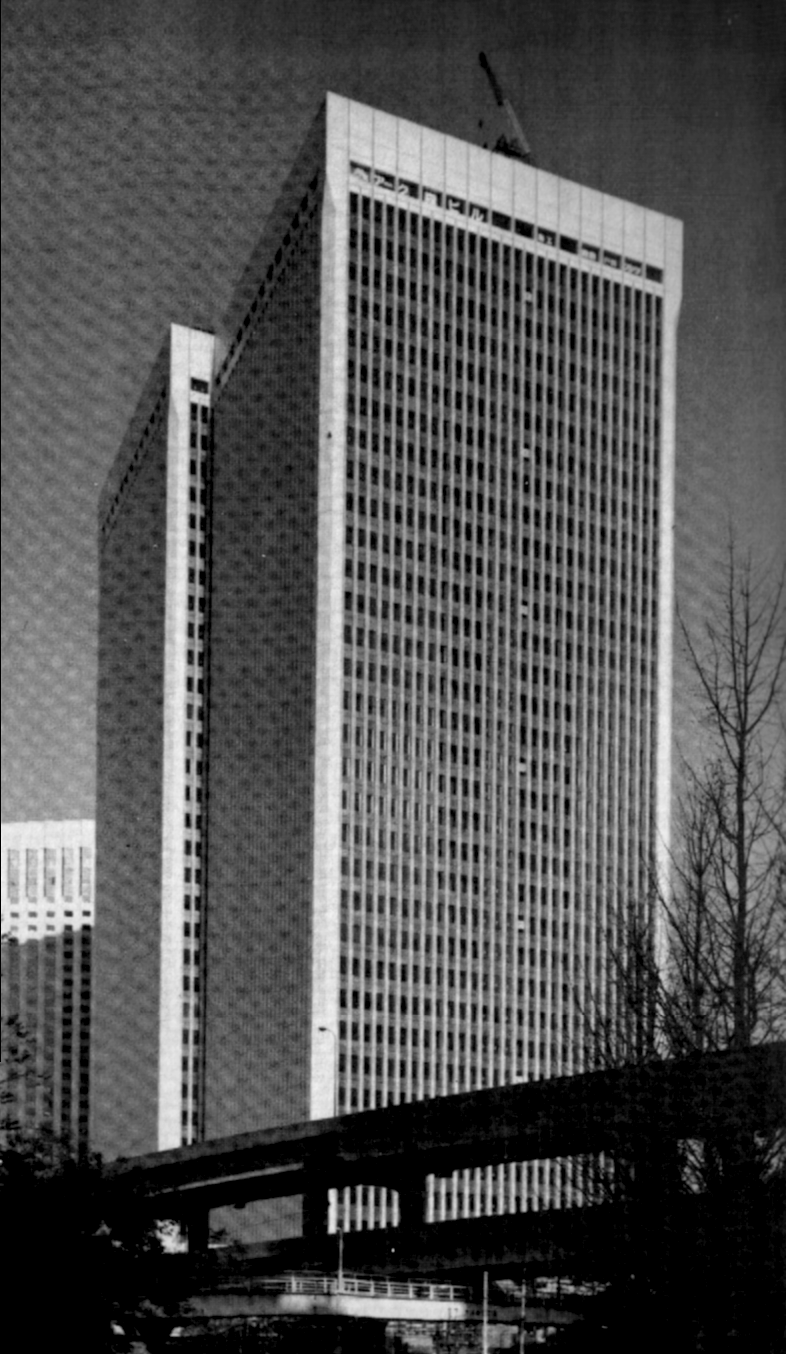

– Cladire cu 37 etaje realizata din compozite Sticla,/ epoxi – Proiect si executie Kajina Corp..

In India nevoia de locuinte este imensa. De aceea Guvernul Indiei a comandat un studiu privind oportunitatea dezvoltarii unui program national pentru construirea de locuinte ieftine din materiale compozite. Studiul a fost realizat de Technology Information, Forecasting & Assessment Council. Unele concluzii ale studiului au fost publicate pe internet (la adresa www.tifac.org.in/news/build) sub forma a doua articole intitulate sugestiv: “Composites – The Future Building Material” (“Compozitele – materialul pentru constructii al viitorului”) si “Composites: A Vision For The Future” (Compozitele: o viziune pentru viitor”).

Fig.1 Scoala in Davwentry – Anglia

(Proiect COPA, executie Scott Bader Ltd.).

Fig. 2 Constructie industriala din Sticla/Poliester

(Stanlei Oswitch-Whessde Ltd, S.U.A.).

Fig. 3 Cupola de la Sports Center din Newcastle on Tyne realizata din Sticla/Poliester.

(N. V. Hooker Chemical S.A., Bruxelles, Belgia si Scott Bader-Anglia)

Fig. 4 Cladire cu 37 etaje realizata din materiale compozite (Kajina Corp.)

Use: 33,000m2 of GRP sandwich panels act as dividers between the rooms and the 200m high atrium. GRP used for freedom of design, high strength, low maintenance costs, high fire retardancy and good sound insulation. Due to low weight, transportation and installation are easier and more cost effective.

Environment: Coastal environment, high UV levels.

Geometry: GRP sandwich panels.

Further Information: Client: HH General Sheikh Mohammed Bin Rashid Al Maktoum, Crown Prince of Duabi Consultants: WS Atkins Overseas (WSAO). Contractor: Al Habtoor Murray Roberts Joint Venture (AHMRJV).

Fig. 5. Arabian Tower Hotel

Environment: In Avon two approach roads of dual two-lane motorway link the M4 motorway at Awkley and the M5 Motorway at Lawrence Weston to a new interchange at the main estuary crossing embankment at Pilning. The total length of the new motorways is 15km. Some 24 new structures are provided, seven of which incorporate advanced composite enclosure systems for improved maintenance life. The scheme also involves the realignment of 12 side roads.

Trials: Traffic studies, geotechnical investigations, planning and environmental considerations were carried out. Preferred routes were selected after public consultation and the submission of a Parliamentary Bill for which client support was provided at Select Committee stage.

Further Information: Maunsell Structural Plastics Maunsell House, 160 Croydon Road, Beckenham, Kent, BR3 4DE.

Fig.6 Severn Bridge Enclosure

Fig. 7. Bromley South Bridge, Kent

Use: Bromley South Bridge is the major element of a road built to remove traffic from the town centre. It passes between residential and business areas, and includes a crossing over the main line railway. The plate girders of the main spans of the bridge are enclosed in a GRP membrane enclosure, in order to provide access for inspection and maintenance and to enhance the appearance of this section of the bridge. The ‘caretaker’ system was used with ACCS components. Great importance has been given to the appearance of the scheme. The bridge parapets, pier and abutments are clad in intricately patterned brickwork, with panels manufactured from GRP to simulate brickwork.

Environment: The length of the bridge is 210m, made up of ten spans, with a main span of 42m. The three principal spans, over the railway, have seven variable depth plate girders with a composite concrete deck. The seven approach spans are a uniform depth concrete slab, supported on slender columns.

Geometry: GRP.

Further Information: Maunsell Structural Plastics Maunsell House, 160 Croydon Road, Beckenham, Kent, BR3 4DE.

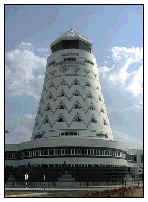

Use: The shape of the structure was defined by the architects and has important religious significance. Several alternative materials were considered, including steel, aluminium and GFRP. GFRP was selected as this offered the most economic solution, both in terms of initial and through-life costs and is also non-conductive, therefore allowing aerials and antennae to be fitted inside the structure. The structure was manufactured in the UK in sections and assembled on the ground in two pieces. As the structure was reasonably light it was easily lifted into position using a mobile crane.

Environment: The structure was designed to withstand high wind loads and seismic loading, where the lightweight solution was advantageous in minimising the inertia loads applied to the supporting cabin structure.

Geometry: Complex frame.

Fig. 8 Harare International Airport

Joining: Bonded & bolted.

Type of Application: Structural.

Requirements: Initial Cost; Durable; Lightweight; Whole Life Cost; Electrical Non-Conduction.

Further Information: CETEC CONSULTANCY LIMITED Coopers House The Horsefair Romsey Hampshire SO51 8JZ.

Use: Complete composite bridge – worlds first advanced composite road bridge Composites used for cost savings, provide low maintenance and good durability.

Environment: The bridge is 8.2m long and 4.3m wide carrying a single lane of traffic.

Geometry: The 8.2m span bridge deck is manufactured from ACCS. There are a series of pultruded GRP sections running longitudinally which are bonded together using an epoxy resin to form a cellular box girder with six main cells which are filled with epoxy foam. The deck is a ‘double ply’ of ACCS skins with cells running in two orthogonal directions. The total weight of the ACCS deck and surfacing is 4.5 tonnes for 35m2 of deck area giving a live to dead load ratio of 13.5.

Joining: Epoxy GRP.

Further Information: Maunsell Structural Plastics Maunsell House, 160

Fig. 9. Bonds Mill Lift Bridge Croydon Road, Beckenham, Kent, BR3 4DE.

Use: The solution was found by providing external FRP reinforcement under a design and install contract. Following careful preparation of the concrete by the specialist applicator, eleven layers of vertically aligned and two layers of horizontally wound carbon fibre sheets, were installed by hand lay-up around the rectangular tapered cross-section of the support. Each layer was impregnated by resin saturant and finally protected from ultra-violet light by a protective coating.

Environment: Exposed to salt spray, rain and direct sunlight. Vehicle impact loads to Highways Agency Standard BD 21/97.

Trials: Transport Research Laboratory load testing and application trials on the A30 Bible Christian Bridge, Cornwall.

Geometry: Rectangular jacket.

Type of Application: Strengthening.

Further Information: TONY GEE AND PARTNERS TGP House, 45-47 High Street, Cobham, Surrey KT11 3DP.

Fig.10. Sycamore Lane Footbridge – Warrington

Use: GRP profiles form the structural elements adding value to construction, living conditions and maintenance. GRP also use for thermal insulation as well as high corrosion and weather resistance. Due to low eight, transportation and installation are easier and more cost effective.

Environment: 5-storey structure, 15m high, ground area 10m x 12m.

Geometry: Pultruded GRP profile.

Further Information: Fiberline.

Fig.11. Eyecatcher Building

Use: Bridge deck is of sandwich construction with girder sections hand laminated along with the internal structure. The GRP deck is covered with a rubber layer made from recycled car tyres. The span is suspended from steel masts and suspension cables attached to steel parapet posts bolted to the deck structure. Composites were chosen for light-weight, excellent durability and low maintenance. A single piece construction allowed for a quck installation, reducing the time when the A30 had to be closed to 24 hours.

Fig.12. Halgavor Bridge

Environment: Cyclists, walkers and horse riders will use the bridge. It is constructed in three parts, 8.5m x 2m and with the main span 32m long. The bridge is 4m wide.

Geometry: Bridge deck is of sandwich construction with girder sections hand laminated along with the internal structure.

Further Information: halgavor.bbcl.co.uk.

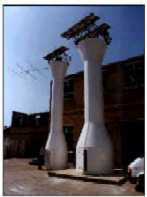

Use: The structures were designed for wind speeds of 162mph and have already survived several tornadoes that are prevalent in this part of the world. The panels are moulded using a resin injection process and so far over 300 towers have been constructed. This design has also been extended to towers up to 15m high for locations in other parts of the world.

Environment: Exposed Very high wind loads.

Geometry: Curved panels.

Joining: Curved panels.

Type of Application: Structure.

Requirements: Durable.

Further Information: CETEC CONSULTANCY LIMITED Coopers House The Horsefair Romsey Hampshire SO51 8JZ.

Fig.13. GRP Light Stations

Fig.14. Aberfeldy footbridge

Use: This is the world’s first major advanced composite footbridge. Maunsell worked closely with Dundee University whose final-year bridge engineering students provided the bridge erection team. A unique method of erection of towers, cables and deck was used which needed no site craneage. This was made possible by the lightweight components. The bridge was completed by the addition of GRP handrailing and a wear-resistant deck finish, providing a life to first maintenance of over 20 years. The minimal foundations and rapid site assembly meant that the solution was very cost effective for the client. Key benefits from using composites are: Fully bonded composite structure Light and durable Erected without craneage.

Environment: The bridge is a cable-stayed structure with a main span of 63m and two back spans. It is stayed from two 18m-high ‘A’ shaped GRP pylons using Parafil cables – Kevlar aramid fibres sheathed in a protective low density polyethylene coat. The 120m-long fully bonded lightweight deck was assembled on site in only ten weeks.

Further Information: Maunsell Structural Plastics Maunsell House, 160 Croydon Road, Beckenham, Kent, BR3 4DE.